Textile Pigment Ink/Dtg Pigment Ink

a. When mixing ink, add as few inks of different colors as possible. The fewer types of color inks, the better the mixing effect.

b. Adopt the principle of "from light to dark", no matter formulating light-colored or bright colored ink, be careful when the hue is close to the sample. It is best not to mix the inks produced by different manufacturers, and try to use inks of different colors from the same manufacturer for color matching, otherwise the phenomenon of uneven color tone will occur, and in severe cases, condensation will occur and the ink will be scrapped.

c. Some screen printing inks are dried by drying, light colors are lighter after drying than undried ones, and dark colors are darker after drying. In addition, whether the color tone of the ink is different before and after drying during printing is a problem that is easy to ignore. Generally speaking, through natural drying (solvent volatile ink), the substrate is plastic, metal, paper, glass, etc., and the color will not change; but if it is a color material for ceramics, the color will only develop after burning and oxidation. , can only be adjusted by experience. For screen printing inks dried by heat curing and light curing, the color changes in shades, as mentioned above. When the amount of ink adjustment is large, you can use the ink mixing machine, Dtf Ink can complete the color adjustment in a short time.

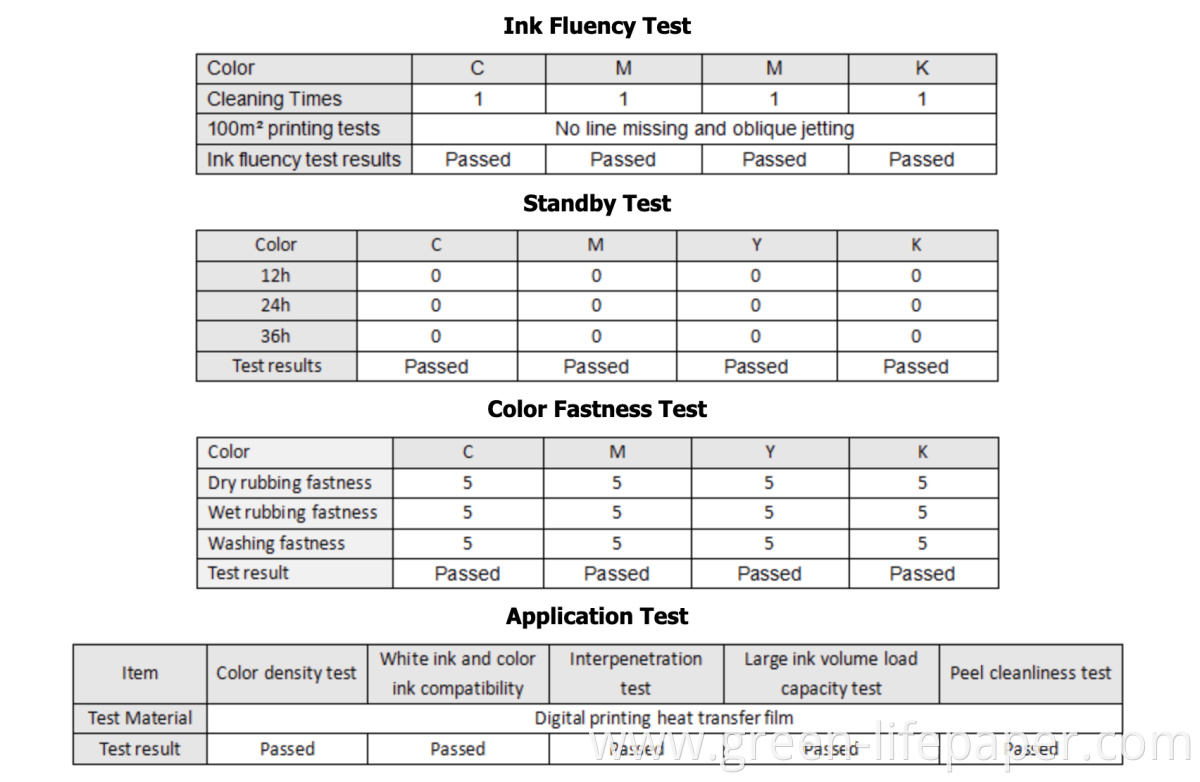

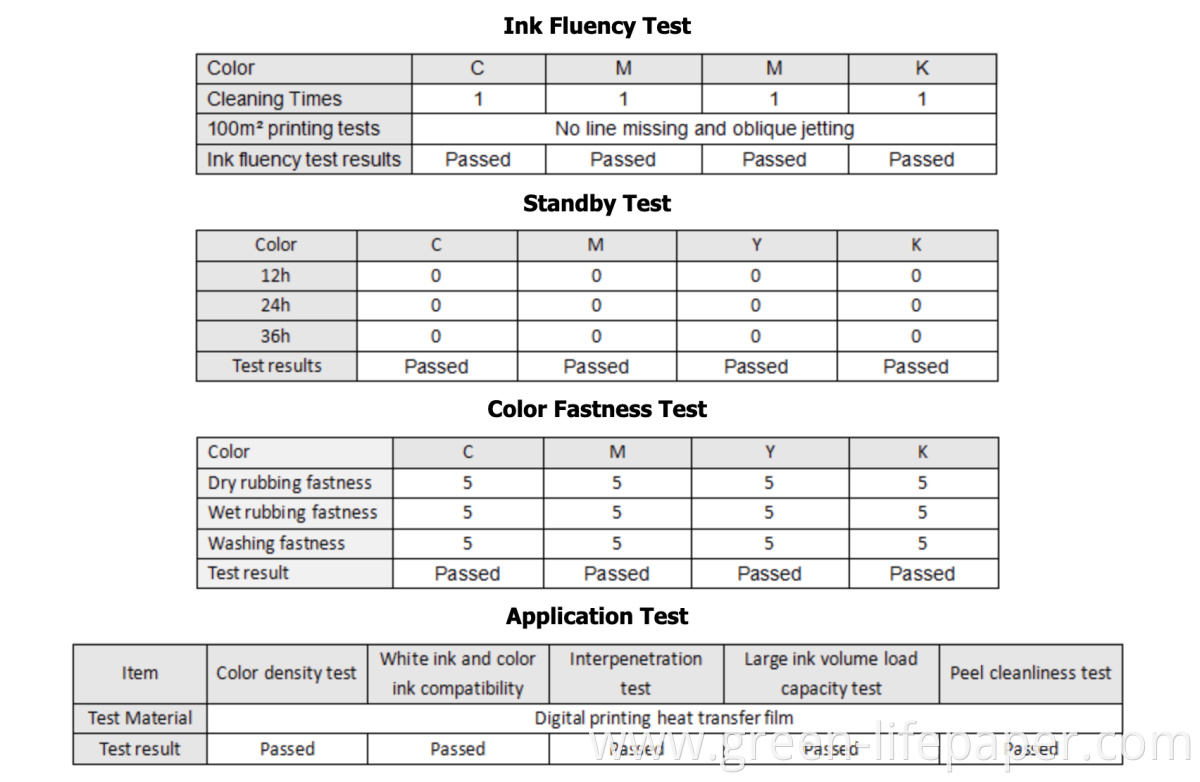

- Solved the problem of weak color,low color fastness and stiff hand feeling problems in printing;

- Use high-performance materials to improve the tensile strength,flexibility and color fastness of the ink;

- The white ink has the pure white base with the strong coverage.The color ink is bright with high saturation.

Color K C M Y W

For use with printers

Epson I3200/4720/5113/DX5 heads DTGprinters

Application

Garment T-shirt,Cut pieces direct printing

Process flow

Pretreatment of textile fabrics:black clothes and dark clothes are sprayed evenly with pretreatment liquid,and then dried (temperature 150℃,time 1 minute),white clothes and light-colored clothes are evenly with treatment liquid,and then dried (temperature 150℃,time 1 minute).

Digital inkjet printing:It can be printed in white ink and color ink at the same time;it can also be printed by printing white ink first and then color inks.